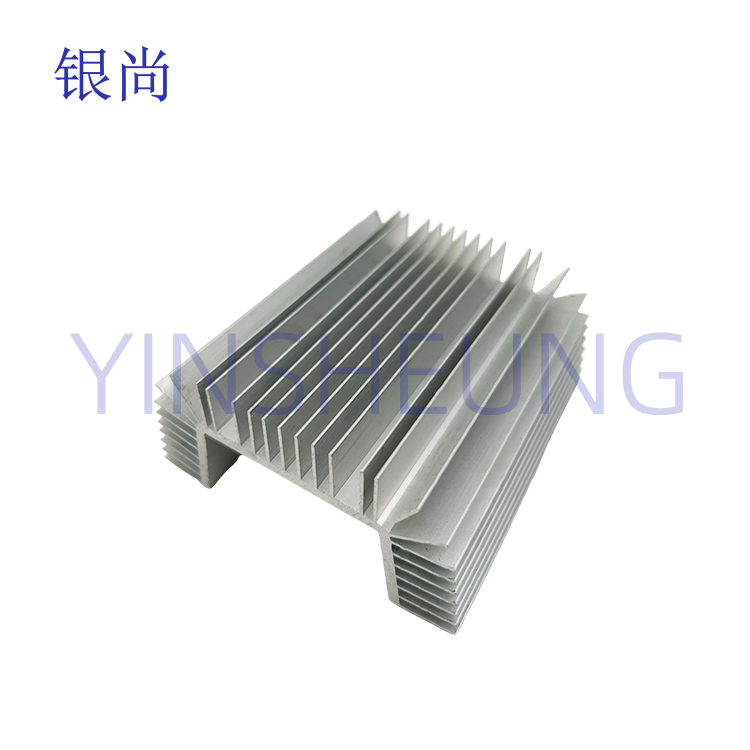

Is the thicker the aluminum profile heatsink the better product?

Not necessarily — thicker aluminum profile heatsink are not always better. Here's a more accurate way to evaluate:

When a thicker heatsink is better:

-

Higher heat dissipation requirement: Thicker profiles have more surface area and mass, which can help dissipate more heat, useful in high-performance or industrial systems.

-

Structural strength: Thicker profiles are more rigid and durable, suitable for heavy-duty or high-pressure environments.

When thicker is not better:

-

Overengineering: If the heat load is low, a thicker profile just increases cost and weight without significant performance gain.

-

Cooling system limits: If the airflow (fan or natural convection) is not strong enough, the extra thickness won't help — it might even trap heat.

-

Material waste: Thicker aluminum uses more raw material, so it's less efficient in cost and sustainability unless truly needed.

What really matters:

-

Thermal design (fins, surface area, airflow)

-

Aluminum quality (purity, conductivity)

-

Application matching (right size for the actual cooling demand)

-

Summary:

Thicker aluminum heatsink can be better only when needed for heat load or strength. The best heatsink is one that’s optimized — not just the thickest.