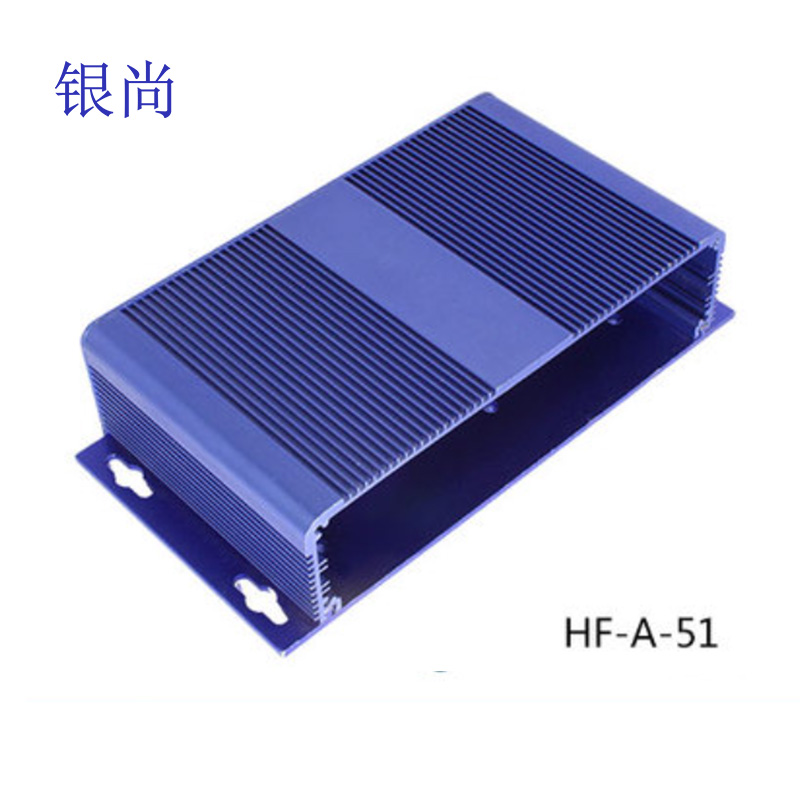

The process of using aluminum or aluminum alloy products as anodes, placing them in an electrophoresis solution for electrophoresis treatment, and using electrophoresis to form an aluminum anodizing film on their surface is called anodizing treatment of aluminum and aluminum alloys. After anodizing treatment, aluminum surface can generate several micrometers to hundreds of micrometers of oxide film. Compared to the natural anondized film of aluminum alloy, its corrosion resistance, wear resistance, and decorative properties have significantly improved and improved.

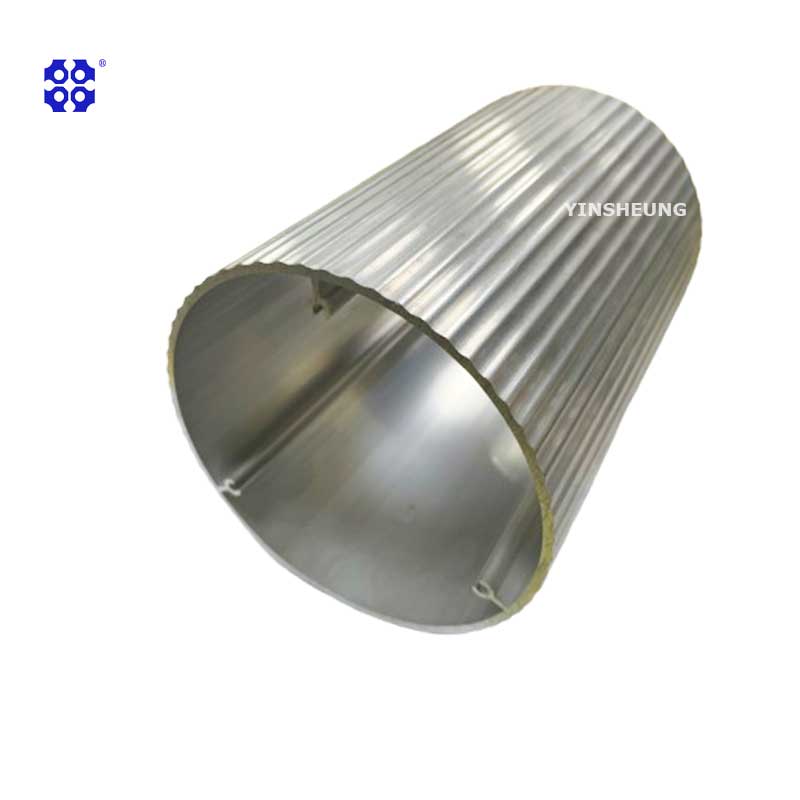

Aluminum alloy tank cars are an inevitable trend in the development of China's tank car market. Lightweight specialized vehicles are a requirement of China's automotive industry in the construction of a new form of socialism with Chinese characteristics, an important component of building a harmonious society, and a necessary path to promote the rapid, sustainable, and healthy development of commercial vehicles in China.Aluminum alloy tank cars are an inevitable trend in the development of China's tank car market. Lightweight specialized vehicles are a requirement of China's automotive industry in the construction of a new form of socialism with Chinese characteristics, an important component of building a harmonious society, and a necessary path to promote the rapid, sustainable, and healthy development of commercial vehicles in China.

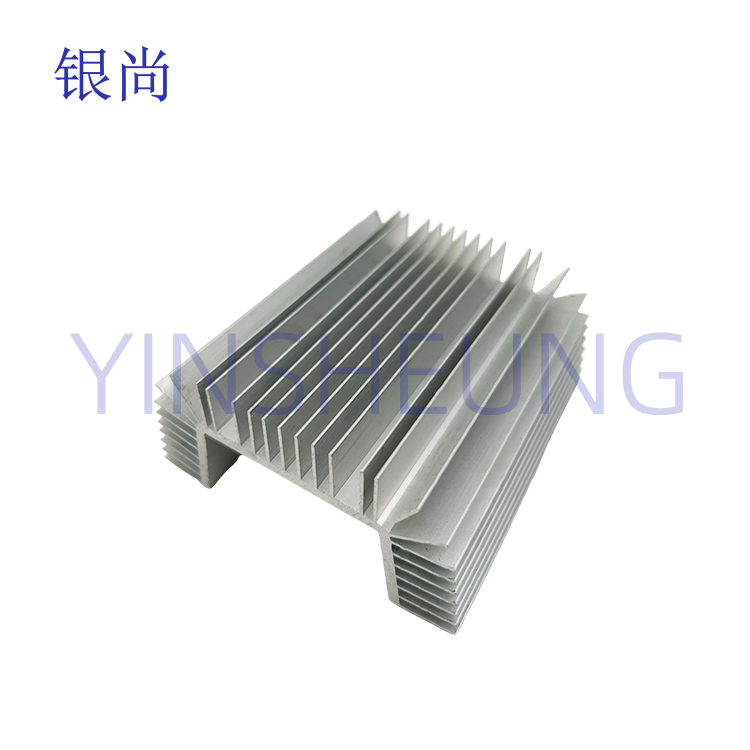

The difference between hard anodizing and ordinary anodizing

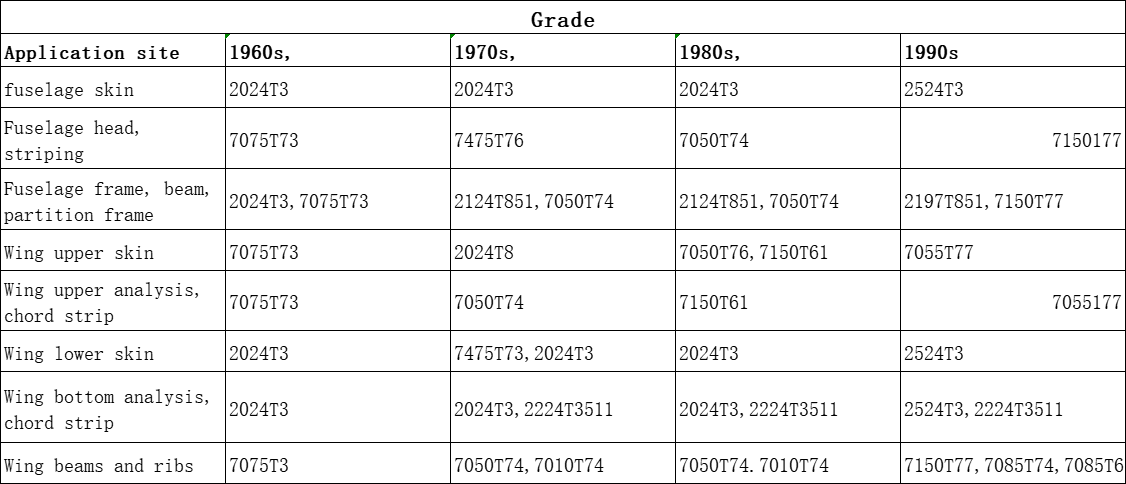

Development Background and Status of Aluminum Alloys for Aerospace Applications